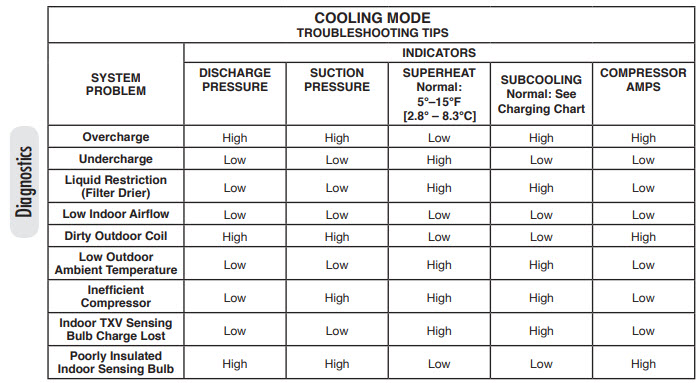

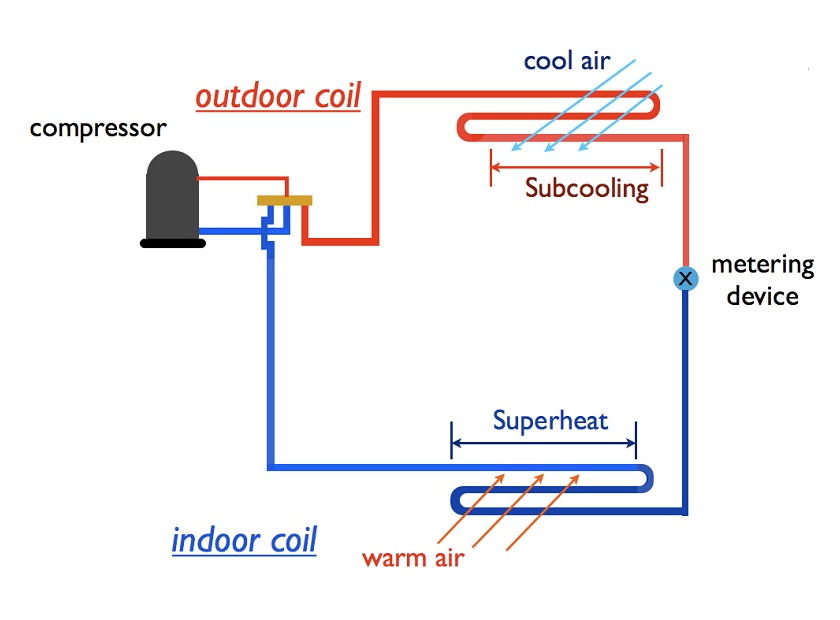

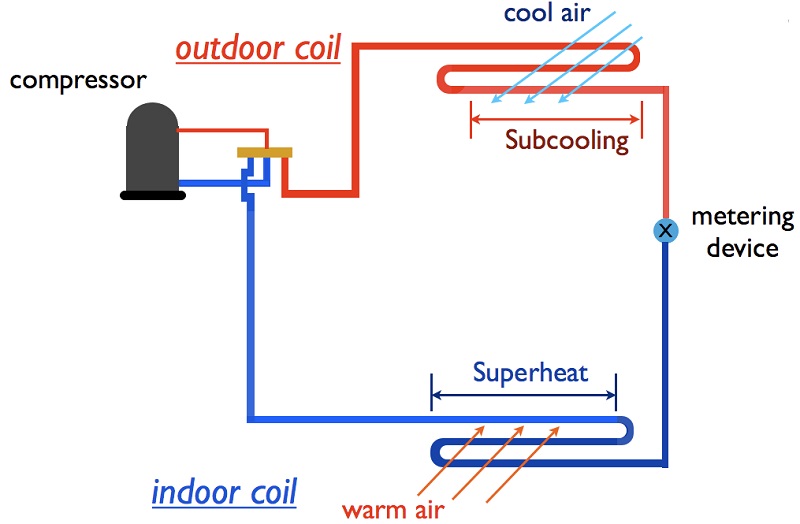

The concept of superheating and subcooling can be difficult to visualize and comprehend. They are two of the most important pieces of information you will need to troubleshoot an air conditioning system. What are superheat and subcooling?

- Superheat is defined as the amount of heat added to a vapor above its boiling point.

- Subcooling is defined as the amount of heat removed from a liquid below its condensing point.

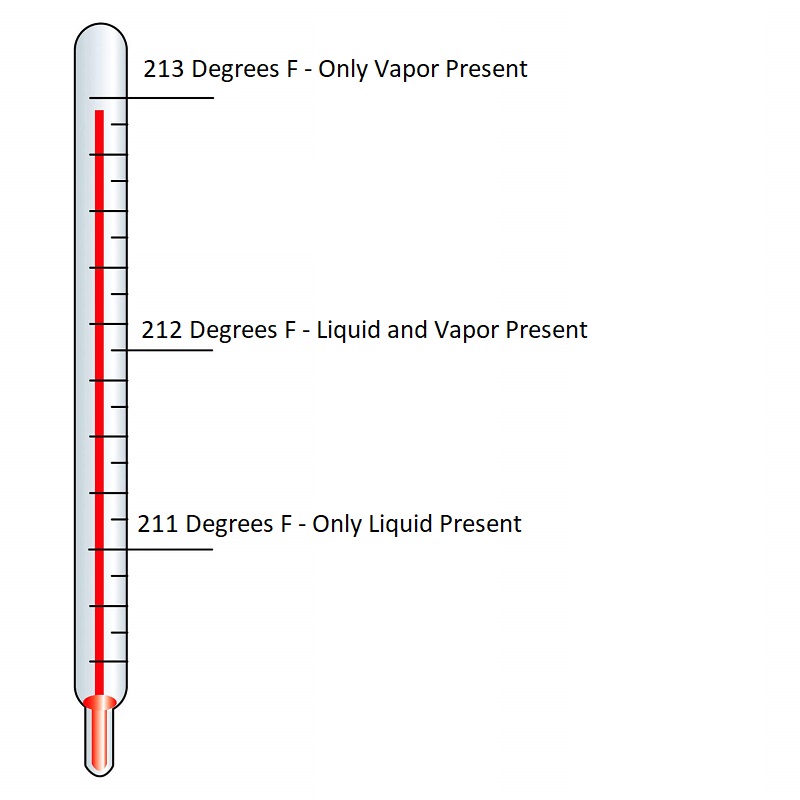

Let's use water as an example to show what is going on. Here is what we know.........

- At 212º F there is both liquid and vapor present

- at 213º F there is only steam present

- at 211º ther is only liquid water present

Any Heat that is added to the steam makes it hotter. This is SUPERHEAT...Heat added to a vapor. If we add 5ºF to the steam (213º F) it now has 5º of superheat and will have a temperature of 218ºF.

Any heat that is removed from the water will make it colder. This is SUBCOOLING...Heat removed from a liquid. If we remove 5ºF from the water (211º F) it now was 5º of subcooling and well have a temperature of 206ºF.

Checking Superheat

Lets pretend you are in front of a condensing unit and have your gauges hooked up, and a temperature clamp (YES you need to BUY one) attached to the bare copper suction line. You record the following information from the low side gauge:

- Suction pressure 140 PSI at 48ºF

- The 48ºF represents the boiling point of the refrigerant at the PSI

- Suction line temperature of 58ºF.

We can conclude that the system has 10º of superheat (Low side boiling point - suction line temperature). What does this mean to you?

- It gaurentees that no liquid refrigerant will get back to the compressor, which could cause failure.

- It gives us a look at what is happening in the evaporator coil. Low superheat shows the boiling point is occuring later in the evaporator coild, high superheat shows the boiling point occuring earlier in the evaporator.

- Superheat is used to charge systems with a fixed orifice.

Checking Subcooling

Lets pretend you are in front of the same condensing unit and have your gauges hooked up, and a temperature clamp (YES you still need to BUY one) attached to the bare copper liquid line. You record the following information from the high side gauge:

- Liquid pressure 354 PSI at 106ºF

- The 106ºF represents the boiling point of the refrigerant at the PSI

- Liquid line temperature of 92ºF.

We can conclude that the system has 14º of subcooling (High side boiling point - liquid line temperature). What does this mean to you?

- The condensing point of the refrigerant is at 106ºF. As the vapor flows through the condenser it gives up heat and turns into a liquid.

- Subcooling is imperative as a solid column of liquid is needed at the TXV for correct operation and "Tells" us what is going on in the condenser. High subcooling shows that the condensing point is occuring earlier in the condenser while low subcooling shows that the condensing point is later in the condenser.

- Subcooling is used to charge systems with a TXV.

Now you can see why knowing what, and why, superheat and subcooling are essential to proper diagnostics and troubleshooting. If they are utilized correctly, they will become second nature to calculate and eliminate guessing.