Blog

-

Remembering Phil Stever (1960-2023)...Continue Read

-

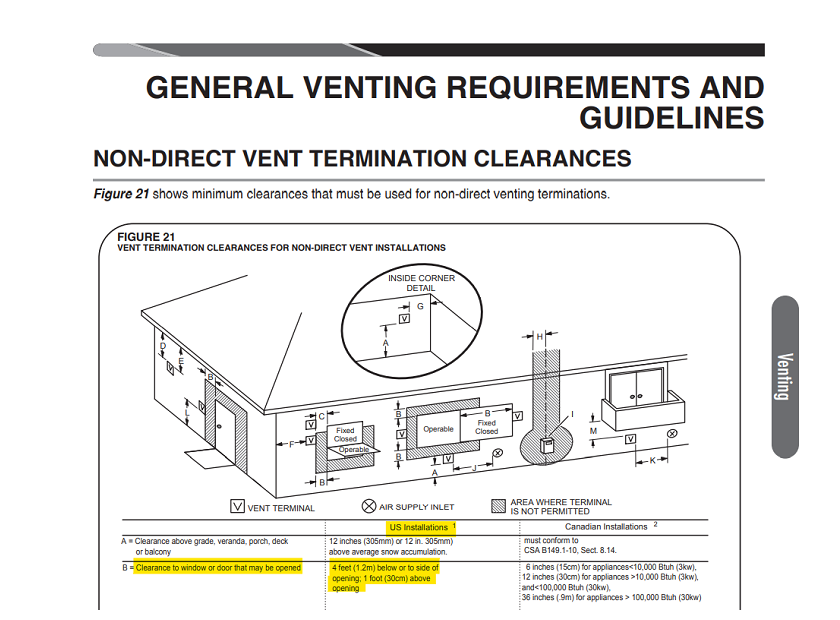

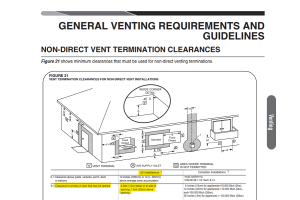

Posted: February 14, 2023Venting 90+ Furnaces...Continue Read

-

2025 HVAC Industry Price Increases...Continue Read

-

<div> <h1>ABR Service & Training Coordinator, David Acciari Awarded the Rheem DSC of the Year Territory 2 for 2021</h1> </div> <p>ABR is…Continue Read

-

New COD Checkout Option...Continue Read

-

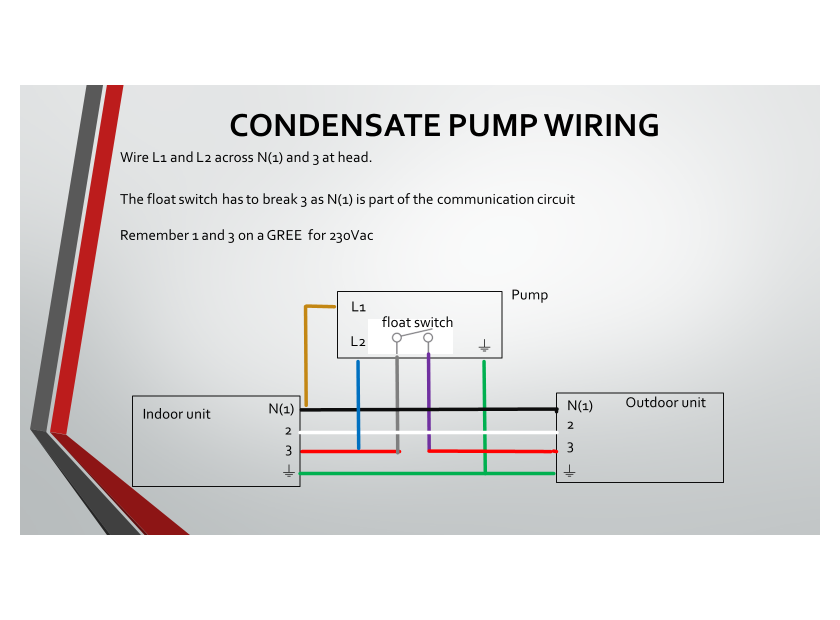

Posted: February 09, 2022Wiring Mistakes - Gree Condensate Pump Wiring...Continue Read

-

Posted: February 07, 2022ABR is your Clean Heat NYS Distributor...Continue Read

-

BNBA Metro Buffalo Impact Study...Continue Read

-

We're excited to announce that our Syracuse branch is moving! When? September 20, 2021 Where? ABR Wholesalers,…Continue Read

-

ABR Wholesalers, Inc. Awarded the Rheem Premier Distributor Performer for 2020 ABR is proud to announce earning the 2020 Rheem Premier Performer award. The seventh award in twelve years. This is due to the dedication and…Continue Read