In the summer of 2019, the opportunity arose to attend a Utica / Dunkirk seminar with Product Engineers and Technical Support.

I recall having a discussion with an engineer, Hongmin Li, and he stated that " Whenever the flame sensor is cleaned or replaced the control and gas valve needs to have an auto-calibration sequence performed for the unit to operate properly" here's why.

The boiler control always tries to maintain the same flame sensing input to the control board, about 3 Microamps. Being that the flame sensor is in the burner section over time it can get coated and/ or corroded. This will reduce the flame sense reading as combustion byproduct acts as an insulator. The boiler sees this input reduction and alters the air/ fuel ratio in an effort to drive the signal back up. Now you show up as the responsible Service/Maintenance tech, replace to flame sensor, pat yourself on the back and off to the next call....then the no heat call comes in. The boiler is using the previous combustion parameters on a new flame sensor. the Boiler attempts to change the combustion ration however it falls out of normal operating parameters and codes out on 128 - loss of flame or 133-failed combustion.

If you clean the flame sensor never use sand cloth. Residual contaminants will turn to glass when heated, glass is an outstanding insulator. See the problem?

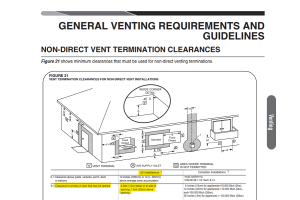

Now we see why the unit has to be recalibrated, let's look at how. The following is taken from the MAC manual.