Some manufacturers ship their evaporator coils with the TXV sensing bulb mounted inside the evaporator cabinet. The installing technician assumes because that's how it came from the factory, that's where it has to be. This is not correct.

It ships this way to protect the sensing bulb and capillary tube during the shipping process.

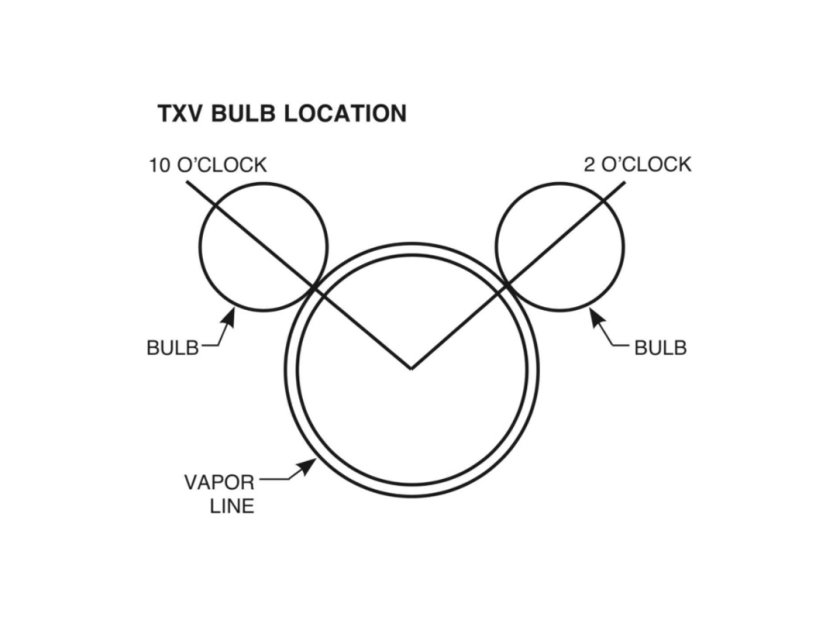

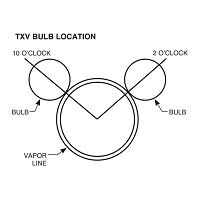

During installation, the bulb is the be removed from the cabinet and suspended freely. After the suction line is brazed and allowed to cool the bulb is to be mounted in the 10 or 2 O'clock position on a horizontal section of suction line within 6" of the evaporator cabinet then insulated to prevent it from sensing ambient temperature.

If you have to mount the bulb vertically the capillary tube must come off the top of the bulb. If the capillary tube comes off the bottom of the bulb the refrigerant charge in the bulb can drain out to the TXV power head rendering the bulb useless. This is referred to as a Charge Migration.

Let's look at what happens if the bulb is left inside the cabinet during heating season. Remember there is refrigerant in the bulb right? Now let's expose that bulb to furnace discharge air of 140F. R 410a at 140f is about 542 PSI. So the refrigerant in the bulb is exposed to 542 psi through 3-6 heat calls per hour, possibly 100 cycles a day for 4-6 months. Ever wonder why the AC doesn't work in the early summer? The diaphragm has failed.

Let's look at what happens if the bulb is left inside the cabinet during cooling. The refrigerant in the bulb provides the opening force (pressure) to the TXV. When placed in a cool environment there is less force. Less opening force equals less refrigerant flow resulting in less efficiency, less dehumidification,longer run times,higher superheat and less compressor cooling.

If the bulb is left attached in the factory position while the suction line is being brazed the heat from the torch (2600F) will migrate into the bulb (braze rod melts at 1200F). The end result is a self induced failed TXV from overheating

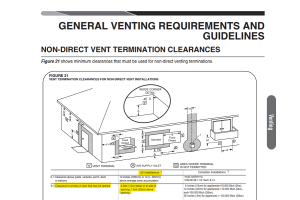

Please see the following excerpt from a manufacturers installation manual.

For OPTIMIUM PERFORMANCE reattach and insulate the bulb at a 10 to 2 o’clock position OUTSIDE OF THE CABINET to the main suction line no more than one foot from the suction line connection. If necessary, the bulb can be installed on a vertical suction line. In this instance, the bulb must be placed before any trap, with the bulb’s capillary tube facing upward.

With best practices being followed the installing contractor can decrease callbacks, instill confidence in themselves resulting in happier customers.